Ethanol Production from Sugar Cane

As I have mentioned before how Ethanol Production from Sugar Cane is important to me. The following is the latest informaton on Ethanol production

Bush set a goal of making the production of cellulosic ethanol competitive in price with gasoline within six years. That goal is ambitious - with current technology, cellulosic ethanol can cost twice as much as conventional ethanol to manufacture. Even the industry's biggest enthusiasts say it will take an infusion of government cash to get the industry off the ground.

General Motors announced two weeks ago that it was going to launch an aggressive marketing campaign, running into tens of millions of dollars, to promote vehicles that can run on the fuel. And investment in it is booming, attracting some of the same people who financed the rapid expansion of Silicone Valley.

Five million cars in the United States can already use a rich mix of 85 per cent ethanol and 15 per cent petrol, and "gasohol" - containing 10 per cent of the biofuel - is widely sold. US ethanol production has quadrupled in recent years.

Several lawmakers, including Sens. Tom Harkin, D-Ia., and Richard Lugar, R-Ind., have introduced legislation to force automakers to speed the introduction of flex-fuel vehicles. The lawmakers also are urging oil companies to make E85 more widely available as the lack of ethanol distribution infrastructure is a significant factor against the taekup of Flex-fuel cars.

Brazil is the world champion. Ethanol from its sugar cane now provides more than 40 per cent of its motor fuel. Two and a half million cars on its roads run on it, and all its petrol contains 25 per cent of the biofuel. More than half the cars in its showrooms are "flexible fuel" vehicles - able to run on this blended petrol, pure ethanol or both

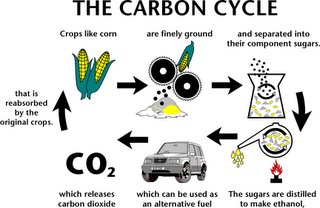

Ethanol Production process from Sugar Cane

1. FUEL CROPS

Corn, wheat, sugar beet and cane, rice, and other crops produce bioethanol. A ton of cane can yield 72 litres.

2. PROCESSED

Sugar cane is rolled to extract the juice, which is fermented. Grain has to be ground up before being fermented and distilled like alcohol.

3. SEPARATED

Ground corn and wheat are treated to separate out the sugars. These are then fermented.

4. DISTILLED

The result is distilled into bioethanol, which, if it is to be added to petrol, as is common, must be further purified.

5. MIXED AND DELIVERED

In the EU, 5 per cent bioethanol can be added to petrol, and in the US's gasohol, 10 per cent. Flex-fuel vehicles can run on up to 85 per cent.

6. INTO YOUR CAR

To run on mixtures greater than 15-20 per cent bioethanol, cars must be adapted to alter the compression ratio or spark timing.

7. AND CO 2 IS RECYCLED

The carbon dioxide expelled by your car will be consumed by plants, some of them fuel crops.

The following is a good newsweek article and my summary on Ethanol fuel

Bush set a goal of making the production of cellulosic ethanol competitive in price with gasoline within six years. That goal is ambitious - with current technology, cellulosic ethanol can cost twice as much as conventional ethanol to manufacture. Even the industry's biggest enthusiasts say it will take an infusion of government cash to get the industry off the ground.

General Motors announced two weeks ago that it was going to launch an aggressive marketing campaign, running into tens of millions of dollars, to promote vehicles that can run on the fuel. And investment in it is booming, attracting some of the same people who financed the rapid expansion of Silicone Valley.

Five million cars in the United States can already use a rich mix of 85 per cent ethanol and 15 per cent petrol, and "gasohol" - containing 10 per cent of the biofuel - is widely sold. US ethanol production has quadrupled in recent years.

Several lawmakers, including Sens. Tom Harkin, D-Ia., and Richard Lugar, R-Ind., have introduced legislation to force automakers to speed the introduction of flex-fuel vehicles. The lawmakers also are urging oil companies to make E85 more widely available as the lack of ethanol distribution infrastructure is a significant factor against the taekup of Flex-fuel cars.

Brazil is the world champion. Ethanol from its sugar cane now provides more than 40 per cent of its motor fuel. Two and a half million cars on its roads run on it, and all its petrol contains 25 per cent of the biofuel. More than half the cars in its showrooms are "flexible fuel" vehicles - able to run on this blended petrol, pure ethanol or both

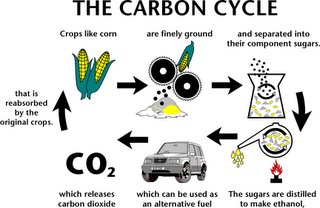

Ethanol Production process from Sugar Cane

1. FUEL CROPS

Corn, wheat, sugar beet and cane, rice, and other crops produce bioethanol. A ton of cane can yield 72 litres.

2. PROCESSED

Sugar cane is rolled to extract the juice, which is fermented. Grain has to be ground up before being fermented and distilled like alcohol.

3. SEPARATED

Ground corn and wheat are treated to separate out the sugars. These are then fermented.

4. DISTILLED

The result is distilled into bioethanol, which, if it is to be added to petrol, as is common, must be further purified.

5. MIXED AND DELIVERED

In the EU, 5 per cent bioethanol can be added to petrol, and in the US's gasohol, 10 per cent. Flex-fuel vehicles can run on up to 85 per cent.

6. INTO YOUR CAR

To run on mixtures greater than 15-20 per cent bioethanol, cars must be adapted to alter the compression ratio or spark timing.

7. AND CO 2 IS RECYCLED

The carbon dioxide expelled by your car will be consumed by plants, some of them fuel crops.

The following is a good newsweek article and my summary on Ethanol fuel

0 Comments:

Post a Comment

<< Home